You'll want a Muskegon remodeler who understands Michigan Residential Code, schedules inspections and utility shutoffs around lakeshore seasons, and checks lead times before demo. We measure, create space plans, and supply permit-ready MEP drawings, then install with kiln-dried hardwood cabinets, Grade 1 hardware, quartz tops, ANSI A108 tile, and NEC/GFCI/AFCI compliance with correct ventilation CFM and makeup air. Anticipate line-item pricing, a critical-path schedule, and weekly updates with documented options for variances. Discover how this approach safeguards budget, timing, and performance.

Critical Insights

- Accredited Muskegon design-build team delivering permit-ready plans, detailed budgets, and clear schedules with consistent progress updates.

- Comprehensive understanding of Michigan Residential Code, inspections, GFCI/AFCI, ventilation CFM, and tempered glazing near ranges.

- Organized procurement with local suppliers to validate lead times prior to demolition, limiting downtime and change orders.

- Premium-grade materials: hardwood cabinetry that's kiln-dried, Grade 1 hardware, quartz countertops, ANSI A108 tile assemblies, and water-resistant substrate materials.

- Seasonal planning for lakeshore climate: hardwood adaptation, winter curing schedules, vent terminations and makeup air designed for resistance to freeze-thaw conditions.

The Reasons Why Local Knowledge Is Important in Muskegon Kitchen Remodeling Projects

From permits through product delivery timelines, local expertise maintains your Muskegon kitchen remodel on budget, compliant, and efficient. You gain advantages through contractors who are familiar with municipal plan review cycles, inspection sequencing, and current Michigan Residential Code requirements for electrical load calculations, GFCI/AFCI protection, ventilation CFM, and tempered glazing near ranges. Local expertise streamlines trade coordination, identifies reliable suppliers, and anticipates utility shutoff windows.

You'll prevent scheduling setbacks since a local pro confirms lead times on cabinets, panel upgrades, and solid-surface fabrication before demolition. Seasonal considerations matter on the lakeshore: humidity impacts hardwood acclimation, winter temps affect curing times, and freeze-thaw cycles impact exterior vent terminations and make-up air compliance. Local teams arrange rough-ins around weather, protect finishes in transit, and preserve clear permit documentation to close inspections swiftly.

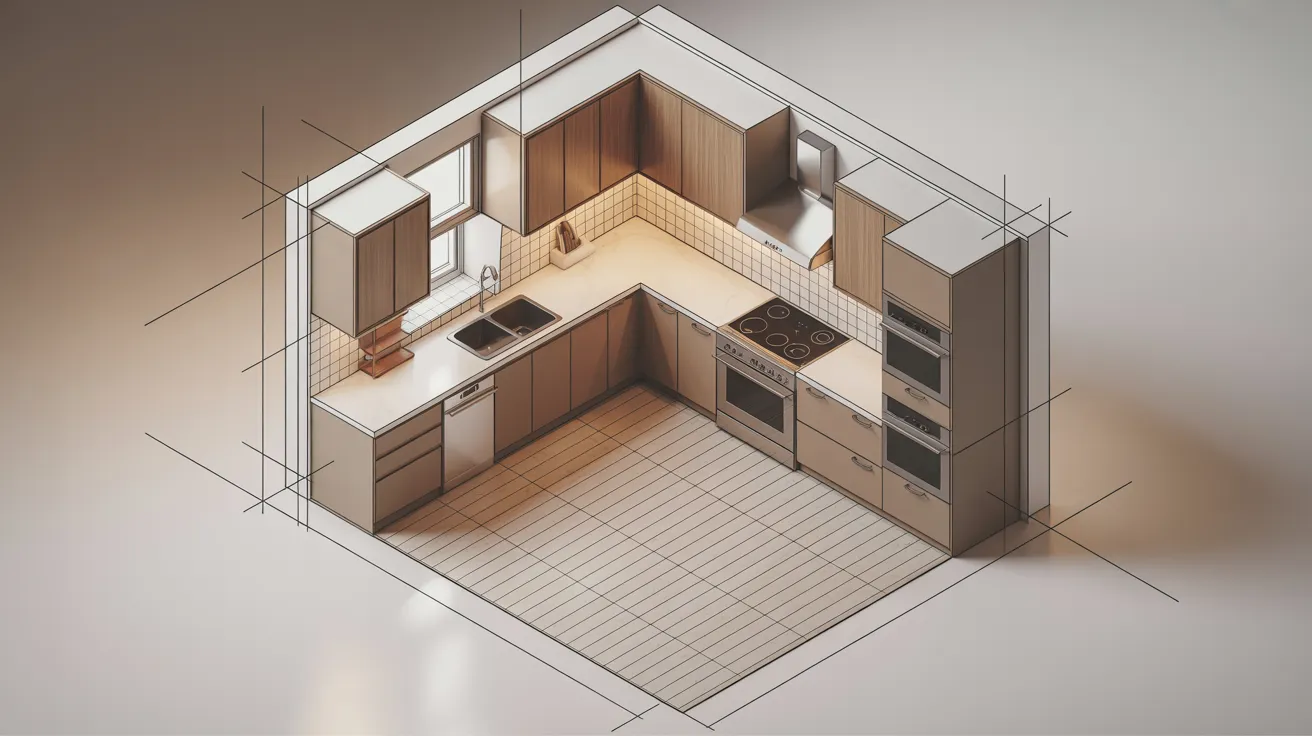

Design-Build Approach: From Vision to Finished Space

Local expertise only provides value when it's structured through a transparent, responsible design-build process. We start with discovery: measure existing conditions, verify utilities, and document code constraints. Next we create space planning that maximizes work areas, flow, and clearances according to IRC and local modifications. You examine schematic alternatives and an initial budget linked to quantities.

Subsequently, we develop permit-ready drawings: plans, elevations, MEP layouts, and specifications matched with energy and ventilation standards. During the preconstruction phase, we establish project scope, schedule, and contractor coordination, sequencing trades to limit downtime and protect your home.

Work advances per a documented schedule, with workplace safety standards, daily logs, and inspections at milestones. You receive transparent change management and punch-list resolution. Closeout includes as-builts, warranties, and post-occupancy check-ins.

Quality Materials and Expert Craftsmanship That Stand the Test of Time

While design establishes intent, durability comes from disciplined material selection and verified workmanship. You receive long-life performance when every component satisfies spec and every connection is executed to standard. We source kiln-dried Solid hardwood for cabinet frames and doors, assembled with mortise-and-tenon and dovetail construction to resist racking. Hinges and slides are ANSI/BHMA Grade 1 for cycle durability. For work surfaces, Quartz countertops deliver nonporous hygiene, high compressive strength, and consistent slab coloration.

We implement moisture-resistant substrates in proximity to sinks, sealed end-grain, and stainless fasteners to inhibit corrosion. Tile assemblies comply with ANSI A108 with crack isolation when required. Backsplash and penetrations are treated with silicone rated for food zones. Electrical boxes, GFCI protection, and appliance clearances are compliant with NEC. Venting, makeup air, and finishes comply with manufacturer requirements to preserve warranties.

Budgeting, Project Timelines, and Honest Communication

Built on that same rigor, your project plan synchronizes scope, budget, and schedule with the same specificity we apply to materials and code. We initiate cost planning that details labor, fixtures, finishes, permits, and contingencies, so you understand line-by-line implications before approvals. You'll get a baseline schedule with critical path activities, inspection milestones, and lead times for custom components.

We maintain a consistent communication rhythm: every week's progress summaries, change-order confirmations within 24 hours, and same-day notice if a issue affects timeline or budget. Changes trigger documented options—de-scope, substitution, or resequencing—each with price and timeline deltas. You approve before we proceed. Permit compliance and inspections are sequenced to avoid idle days. The result: controlled costs, reliable timelines, and no surprises.

Work Examples and Homeowner Reviews

Frequently the strongest proof is the work itself: our portfolio spans full-gut kitchen remodels, ADA-compliant layouts, historic bungalow restorations, and high-performance upgrades that adhere to Michigan Residential Code and Energy Code. You'll see clear scope definitions, stamped permits, and inspected milestones shown through pre-and-post photos, finish schedules, and appliance specs.

We present cabinet box construction, soft-close hardware ratings, and ventilation sizing that satisfies M1503. Range clearances, GFCI/AFCI protection, and tamper-resistant receptacles meet electrical code. Our air sealing, R-values, and LED efficacy fulfill Energy Code targets without diminishing aesthetics.

The metrics are supported by client testimonials. Homeowners highlight dust control, schedule adherence, and punch-list closure. You'll notice precise reveals, even quartz seams, and proper toe-kick recesses. Inspect our warranty terms and service logs to verify performance after move-in.

Questions & Answers

Are Permits and Inspections Handled by the Remodeling Team or Homeowners?

Usually, the remodeling team handles permits and inspections, but you maintain final oversight. We define permit responsibility in the contract, draft code-compliant drawings, submit applications, and coordinate AHJ approvals. We coordinate inspection scheduling, meet inspectors on-site, and address correction notices immediately. You authorize fees and provide property access. If you prefer DIY permitting, we'll furnish documentation and guidance. Our goal: zero surprises, clear accountability, and a compliant project from demo to final.

Do You Offer Accessibility and Aging-In-Place Kitchen Renovations?

Absolutely-we create kitchens that mature beautifully alongside you. Visualize moving along an unobstructed route: barrier-free designs, expanded walkways, lever-style fixtures, and anti-slip floor materials facilitate each step. We integrate reduced-height countertops, extending shelf systems, D-form pulls, and side-access ovens for safe access parameters. Illumination is activity-centered; switches and outlets meet ADA-inspired heights. We specify reinforced walls for upcoming safety bars and threshold-free doorways. You're provided with compliance-focused plans, accurate dimensions, and synchronized reviews, start to finish.

What Types of Warranties Cover Labor and Installed Appliances or Fixtures?

You receive a 2-year check here Labor warranty on installation per contract, fully transferable, and meeting local codes. Appliance coverage follows manufacturer warranties (generally 1-2 years parts/labor), with our certified startup and registration to activate extended protections when available. Fixtures include manufacturer warranties; we cover labor for warrantable defects within our term. Exclusions: misuse, owner-supplied items, and consumables. We offer warranty documentation, serials, and claim support, providing quick, code-compliant remediation.

How Do You Address Unexpected Structural Issues Found During Demolition?

You address unexpected structural issues by stabilizing first and planning fast. With 37% of remodels exposing hidden defects, you implement temporary shoring, document any hidden joist damage, and conduct load-path calculations. You secure circuits, cap unexpected plumbing, and schedule inspections to stay code compliant. You implement contingency budgeting, issue a written change order, and sequence repairs to reduce downtime. You check moisture content, use approved connectors, and pass rough-in inspections before resuming finishes.

Do You Collaborate With Third-Party Interior Designers or Appliance Suppliers?

Yes. You participate in designer collaboration from concept through punch list, providing CAD files, finish schedules, and shop drawings for exact integration. You also manage supplier coordination, validating specifications, lead times, rough-in requirements, and delivery windows. You verify UL/ETL listings, ADA clearances, ventilation CFM, and electrical/gas loads against code. You create submittal packages, coordinate site access, arrange materials, and manage install to meet schedule, budget, and warranty requirements without scope gaps.

Conclusion

You need a kitchen that works perfectly and adheres to code on day one. With regional knowledge, a design-build approach, premium materials, and clear scheduling, you'll achieve consistent results. Here's the proof: homeowners recover an average 85% of a minor kitchen remodel's cost at resale (industry data), proving function and finish pay dividends. Choose a Muskegon team that records specs, secures permits, and reports changes in writing—so your project timeline, budget, and craftsmanship endure daily use and inspection.